Aubrey, TX

The Equation is Simple

The Right Process + The Right Source =

Profit for our customers and long term success for PMIENG

Headquarters

Progressive Manufacturing Ideas

& Engineered Components

PMIeng

Aubrey, TX 76099

817-312-3071

SERVICES

|

|

WHO WE ARE

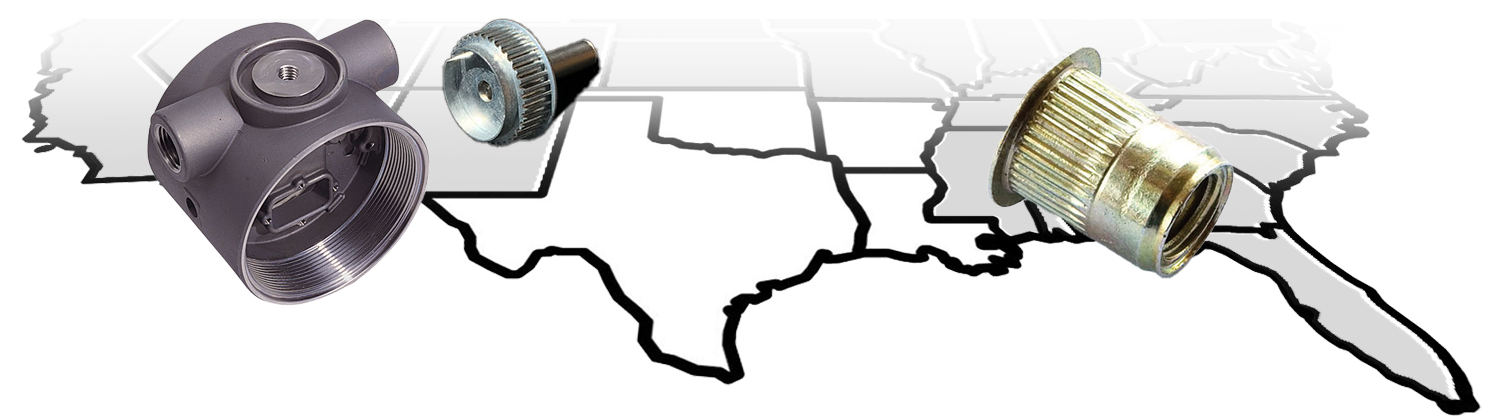

PMIeng has been around since 1976 and has evolved to changes in the market and changes in technologies. Whatever alloy, size of part or quantity needed, PMIeng has processes and companies who can deliver. Finding the best fit for the project is always PMIeng’s objective!

|

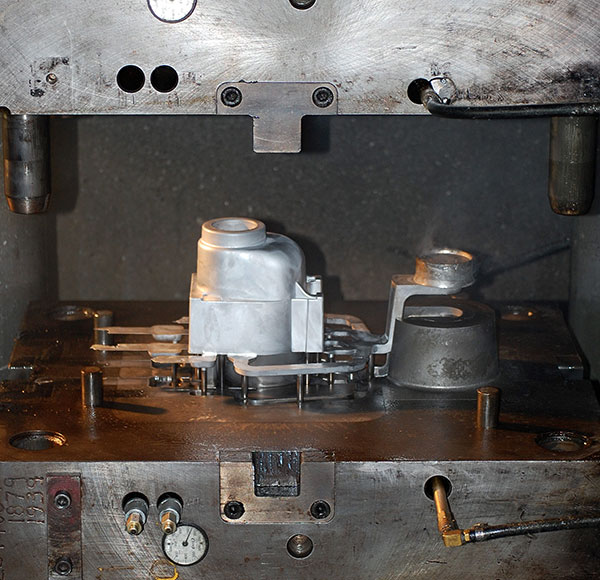

CASTINGS IN GENERAL

Foundries always have a target Mold Revenue and that means different things to different casting processes.

For example: A small part in a sand casting may have to have several cavities in the tool to fill the board to optimize mold revenue, but the tooling may become an obstacle as multi-cavities can get expensive.

In an Investment casting, the mold or sprue is 3 dimensional, therefore, sometimes you can get more on a mold or sprue than in sand, and since the tool and the mold are separate things, your investment cast tool can sometimes actually be less expensive than in sand. While this may not seem intuitive, because IC tooling is more intricate, it can come out that way depending on several variables.

The bottom line is the shape of the part, annual quantity, alloy, dimensional tolerance, cosmetic and strength requirements all come into play when deciding on what process is best for your part.

|

|

|

Web site designed and maintained by Design-2-Part Web Design.