Aubrey, TX

The Equation is Simple

The Right Process + The Right Source =

Profit for our customers and long term success for PMIENG

Headquarters

Progressive Manufacturing Ideas

& Engineered Components

PMIeng

Aubrey, TX 76099

817-312-3071

SERVICES

|

|

WHO WE ARE

PMIeng has been around since 1976 and has evolved to changes in the market and changes in technologies. Whatever alloy, size of part or quantity needed, PMIeng has processes and companies who can deliver. Finding the best fit for the project is always PMIeng’s objective!

|

COLD WAX INVESTMENT CASTINGS

PMIeng provides investment castings to a variety of industries.

VIEW COLD WAX INVESTMENT CASTINGS PDF ▶

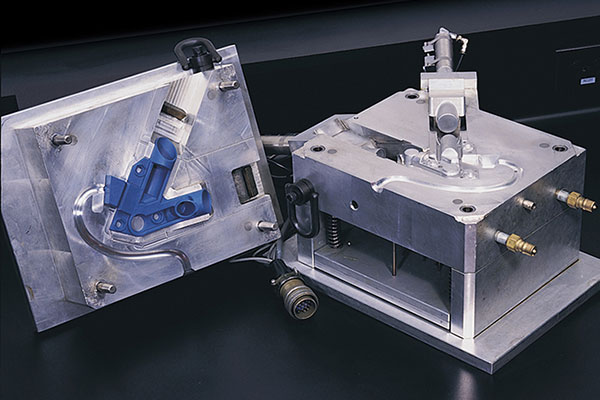

Often called Lost Wax, parts best suited for Cold Wax Investment Casting are typically smaller than a shoe box, unless there is a special cosmetic or precision need for IC on a larger part. An aluminum tool is constructed to inject wax into the wax pattern is ejected and assembled together to form a tree full of wax parts.

The tree is then dipped into ceramic slurry, the slurry dries and they are dipped and dried several times to build up a ceramic shell. This ceramic coated tree of wax is then flipped upside down and de-waxed in an autoclave.

The wax melts out while the ceramic is hardened. Now the hollow ceramic mold is filled with molten metal. The features of the mold vacated by the part geometry, becomes the metal parts.

Once the metal hardens the ceramic is cleaned off with a high-pressure water blast and the tree which was once wax is now bare metal. Parts are then either broken off or sawn off the tree.

These parts can be 3 dimensional, and have complex geometry, as slides are often utilized for holes and features, soluble and Ceramic cores can be used to get complex shaped cores. Surface finishes are typically 125-150 RMS and linear tolerances are very good and depend on part feature.

|

|

|

|

Web site designed and maintained by Design-2-Part Web Design.