Aubrey, TX

The Equation is Simple

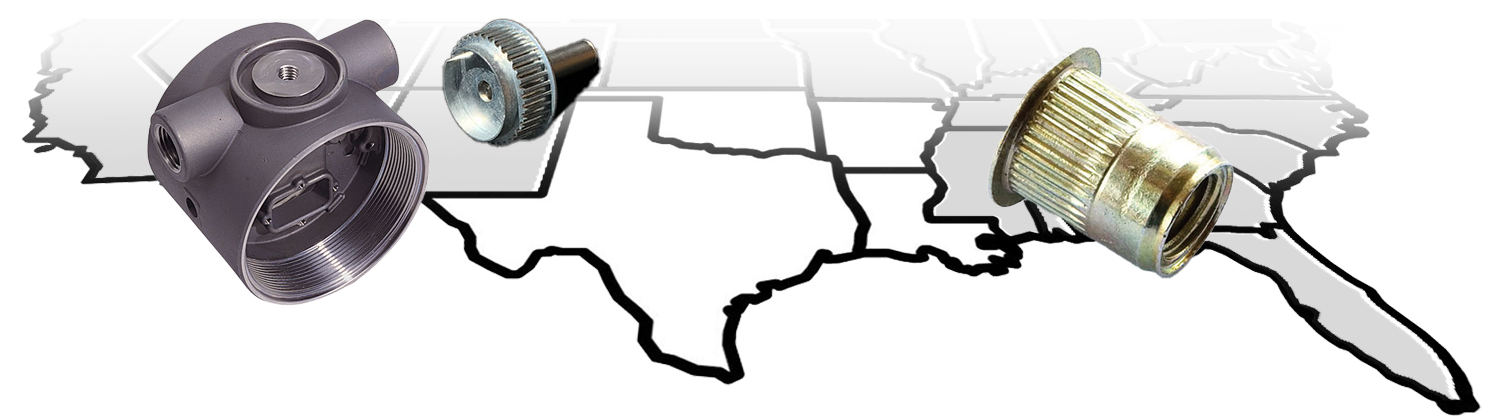

The Right Process + The Right Source =

Profit for our customers and long term success for PMIENG

Headquarters

Progressive Manufacturing Ideas

& Engineered Components

PMIeng

Aubrey, TX 76099

817-312-3071

SERVICES

|

|

WHO WE ARE

PMIeng has been around since 1976 and has evolved to changes in the market and changes in technologies. Whatever alloy, size of part or quantity needed, PMIeng has processes and companies who can deliver. Finding the best fit for the project is always PMIeng’s objective!

|

SAND CASTINGS

PMIeng provides sand casting services to a variety of industries.

There are several variations of sand castings, usually the way the sand is held together, accounts for these variations. The basic premise of sand castings is that there are 2 boxes, the cope (top box) and the drag (bottom box) that are filled with sand. The pattern which can be made of wood, aluminum or other is imbedded into the sand making an impression, or forming a cavity in the sand.

The sand is usually held together with some chemical agent which helps the sand keep its shape or maintaining the cavity when the pattern is extracted. Molten metal is poured into the cavity, when the metal freezes; the part is taken out of the sand and cleaned up for use. Sand casting tooling can be inexpensive and good for small volume and large parts.

The dimensional tolerances tend to be loose, because the sand can move and there can be shift between the cope and drag. The surface finish can tend to be rough due to the coarseness of the sand. Usually a draft is required in the tool in order to extract the pattern from the cope and drag without disrupting the sand.

When pouring metal into the sand, certain issues can arise, such as, the gasses in the metal must have a place to escape and if the sand is too saturated with the chemicals, you can have entrapped gasses in your part. There are several trick foundries use to minimize defects such as venting the pour and bottom pouring to minimize float side debris on the part.

|

|

|

Web site designed and maintained by Design-2-Part Web Design.